ATI Industrial Automation, Inc.

ATI Industrial Automation, Inc.Request A Quote

Apex, NC | 919-772-0115https://www.ati-ia.com/index.aspx

As a team at ATI Industrial Automation, we take pride in our leadership role in providing advanced automation solutions to industries worldwide. Our mission is to deliver innovative, reliable, and high-quality products and services that cater to our customers' evolving needs. In this company description, we would like to highlight our load cell offerings, which deliver exceptional accuracy and reliability in measuring force and weight. Regarding products, we offer a broad range of load cells that are specifically designed to cater to various industrial applications, including tension, compression, and bending. Our load cells come in different sizes and capacities, ranging from miniature to high-capacity sensors, enabling us to meet our customers' varying needs. Our load cells are engineered to provide dependable and accurate measurements, with a low profile and high stiffness that ensures optimal performance. Additionally, our load cells are available in different materials, including aluminum, stainless steel, and high-strength alloy, making them suitable for harsh environments. At ATI Industrial Automation, we provide a comprehensive range of services that complement our products, enabling our customers to derive the most from their investments. Our services include custom load cell design, calibration, repair, and replacement. We have a team of experts who are skilled in designing and building load cells that meet specific customer requirements, ensuring optimal performance and reliability. Our calibration services are traceable to national standards, and they guarantee that our customers' load cells remain accurate and reliable throughout their lifespan. We have a state-of-the-art facility that features advanced testing and manufacturing equipment to produce high-quality load cells that meet the highest industry standards. Our engineers use advanced techniques such as finite element analysis and strain gauging to optimize the load cell design and guarantee optimal performance. Additionally, our load cells undergo rigorous testing to ensure they meet our customers' specifications and are reliable in the most demanding applications. In conclusion, we at ATI Industrial Automation are committed to delivering high-quality, reliable, and accurate load cells that cater to our customers' diverse needs. We aim to provide comprehensive solutions, from design to calibration and maintenance, ensuring that our customers derive the most from their investments. With our advanced technology, state-of-the-art facilities, and team of experts, we are confident in providing exceptional load cell solutions that cater to the most challenging industrial applications. Additionally, as the foremost engineering-based developer of robotic accessories and robot arm tooling globally, we produce the most reliable and flexible line of robotic end effectors in the industry. Customer satisfaction is our top priority, and we are ISO 9001 registered to ensure the highest quality products. We subject each product to demanding quality control and scrutiny before it can leave our factory. Our experienced account managers, with the support of our engineering team, work closely with your staff to find the best solution for your business. Our products are used in an array of industries, including robotics, aerospace, biomedical, automotive, electronics, applied research, academics, nuclear, and governmental applications.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

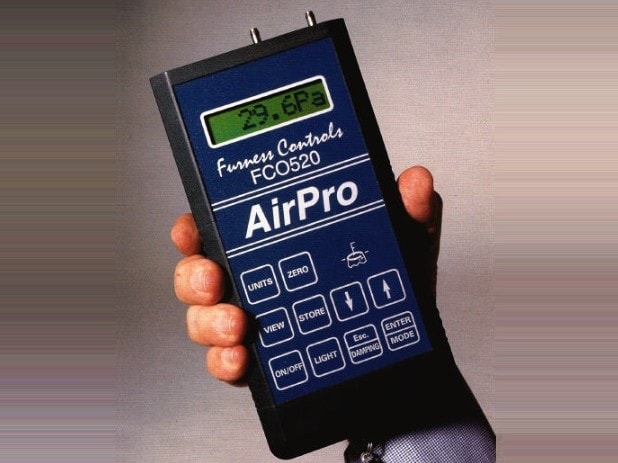

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services