Tension Load Cells

Load cells are transducers which convert pressure or force and give a measurable electrical output. Different types of load cells are used for different applications. For example, when intrinsic safety and hygiene are required, a pneumatic load cell is used. In a situation where use in remote locations is required, hydraulic load cells would be the ideal kind. Read More…..

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

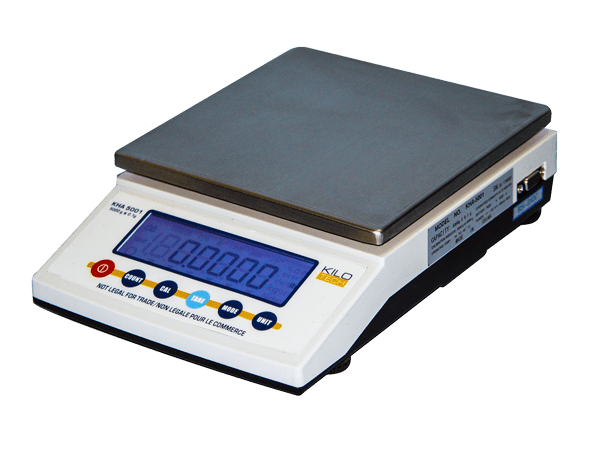

Anyload has been in business for over 20 years. Anyload is experienced in the design and production of high quality standard load cells, specialty load cells, weigh modules, indicators, scales for commercial and industrial applications, and wide varieties of weighing components.

At Coti Global Sensors, we are dedicated to providing top-of-the-line load cell solutions and comprehensive services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted authority in load cell manufacturing, renowned for our commitment to quality, reliability, and customer satisfaction.

More Tension Load Cell Manufacturers

Strain gauge load cells can be used for almost all industrial application and they are very versatile. Tension load cells which are also commonly called compression load cells are ideal for applications where the load may go from tension to compression, or from compression to tension. They are very suitable for environments that restrict space, and their threaded ends allow for easy installation.

Tension load cells are very versatile with low profile and welded stainless steel design. They are very accurate in measuring compression and tension forces. These kinds of tension load cells, especially those that have male threaded stud connections for load attachment, are designed to collect tension and compression information under harsh conditions.

They are also able to measure bi-directional units which range from 1kg to 100 tons in 2" diameter with an FSO linearity of +/- 0.15%. The tension load cells have an internal design that allows for superior long term stability and significantly reduces the effects of small-axis loads. Tension load cells are highly accurate and leave a small foot print.

Some advantages of tension load cells include easy installation, high accuracy, reliability, ability to be customized, high side load reduction, better sealing and protection, small, and inexpensive. Some down sides of the tension load spring are that the strain gauges are exposed and require protection, no load movement is allowed and the loads must be centered.

Therefore, there are a few things to consider when purchasing a tension load cell. The first being the duration of measurement (short-term duration with a tare, or long term duration without a tare), output requirements, direction of loading (tension/compression, or both), percent of accuracy requirement (as a percent of reading or full scale output), operating temperature conditions, options for mounting, certification requirements, operation costs and other accessories needed.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services