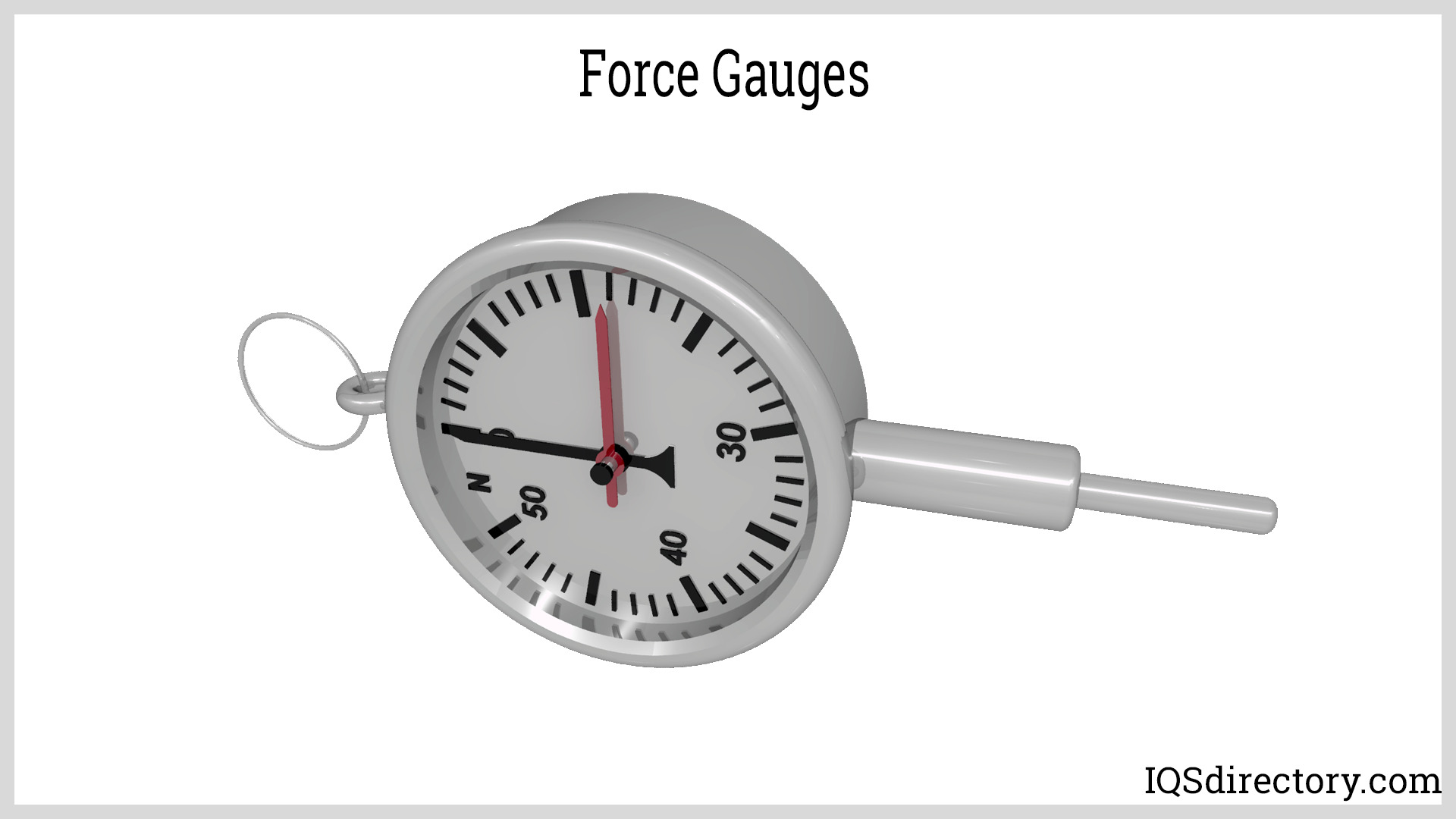

Force Gauges

A measuring device used to measure forces is a force gauge, often known as a force meter. Applications can be found in the field and lab for quality control, production, and research and development. For example, the breaking point of an object, the force needed to open or operate the object, and the material’s elasticity can all be determined through force gauges in engineering and safety testing. Read More…..

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

Anyload has been in business for over 20 years. Anyload is experienced in the design and production of high quality standard load cells, specialty load cells, weigh modules, indicators, scales for commercial and industrial applications, and wide varieties of weighing components.

At Coti Global Sensors, we are dedicated to providing top-of-the-line load cell solutions and comprehensive services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted authority in load cell manufacturing, renowned for our commitment to quality, reliability, and customer satisfaction.

More Force Gauge Manufacturers

Mechanical and digital force gauges are the two primary categories of force gauges. While digital force gauges have a load cell built-in, mechanical force gauges include a spring mechanism. Typically, force gauges measure pressure in escalating levels of stress as well as other human-dependent variables.

Types of Force Gauges

Mechanical Force Gauges

The push and pull forces are measured using mechanical force gauges, commonly called push-pull gauges or push-pull scales, which are analog force-measuring devices for spring mechanisms. A spring mechanism, an analog force gauge, is used in mechanical force gauges. Using a spring or load cell, the measured force amount is converted into a calibrated force value. The operation of mechanical force gauges does not require a battery. Because they rarely have operation problems or malfunctions brought on by outside influences like noise, static electricity, or the elements, they are incredibly strong and simple to handle.

Mechanical force gauges can achieve stable force loading and make it simple to read the transition of force by the movement of the needle. Mechanical force gauges are widely used in many quality control sites due to their sturdy structure and ease of management due to the lack of a need for a power supply. Mechanical force gauges are suggested if your usage is limited due to its inexpensive cost and simplicity of storing.

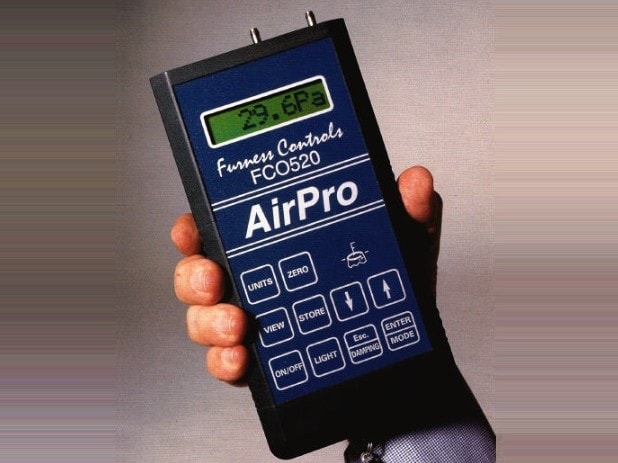

Digital Force Gauges

Digital force gauges are a digital indication that converts the measured force into an electrical signal that can be calibrated, quantified, or digitalized for display using an integrated load cell or strain gauge . They may be connected to a computer because they are digital tools, which makes it simple to store, manage, and analyze data over time. Digital force gauges, instead of mechanical force gauges, can monitor average force values and rapidly varying force levels during impact testing. Nowadays, many models provide consumers the option of selecting the unit of measurement in which they want the reading to be shown.

Preparing numerous devices or performing the conversion for various measurement units is optional. Digital force gauges can also display additional information, such as calibration information, alerts, and more. Because of the many conveniences these features have provided, digital force gauges are now a common option for force measurement and other metrology applications. In addition, by lowering human reading errors, the type of digital readings contributes to accurate data. A digital force gauge is more expensive and requires a battery to operate, though.

Applications of Force Gauges

Force gauges are frequently employed in numerous contexts and sectors to measure compressive and tensile forces.

- Force gauges in ergonomics help determine whether a product is used when interacting with people and whether the required force to use it is reasonable and within the range of motion for most individuals. These uses include opening a door, depressing a machine's button, opening a soda can, etc. For instance, the force required to initiate the movement and shut the door must be known to the automobile maker.

- Force gauges can assess material strength and determine whether a material is strong enough to withstand pressures encountered during operation or transit. In addition, they can check the material's stretchability, braking force, and tensile strength. For instance, a compression test will be performed on the water bottle to see if the compression forces experienced during transit will cause it to leak or shatter.

- Force gauges can be utilized in developing weapons to gauge the amount of recoil in prototype rifles and machine guns. The measurement is crucial to this business because it can ensure user safety and a consistent recoil standard throughout the manufacturing process.

- Professional boxers use force gauges to assess their muscular strength and punching power. In addition, punching balls and other training tools can be fitted with external load cells or pressure gauges to measure punching force.

- To verify the security of use and operation, engineers, designers, or contractors will test the load capacity of the fasteners holding railings or bannisters using force gauges. These tests are frequently used in fields where people's safety is very important.

Benefits of Force Gauges

- Most analog force gauges don't need power, while digital force gauges may be seen at a distance.

- The use of force gauges in temporary installations is necessary for many applications. In addition to mechanical engineering, hydraulics and pneumatics, pumps and compressors, and general service and test operations, force gauges are appropriate for various applications and industries.

- Force gauges often have a stainless steel case, well-designed battery housing, and strong electronics to ensure the longevity of the gauges and consequent accuracy of readings.

- Digital displays can display force gauge readings that are both quick and accurate.

Choosing the Right Force Gauge Manufacturer

To ensure you have the most productive outcome when purchasing force gauges from a force gauge manufacturer, it is important to compare several companies using our directory of force gauge manufacturers. Each force gauge manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each force gauge business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple force gauge companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

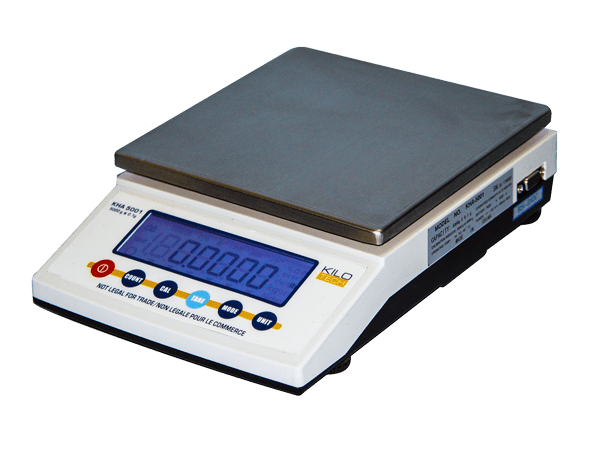

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services