Torque Transducers

Torque transducers, also known as torque sensors and torquemeters, are instruments used to measure and report torque in a system. Understanding torque can be difficult, as the word has different meanings in different contexts, and each of those meanings can be elusive to people without backgrounds in mechanical engineering or physics. The fields that prioritize measuring torque with torque transducers include the automobile, aerospace and aviation industries, and anything else that works with engines. Read More…..

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

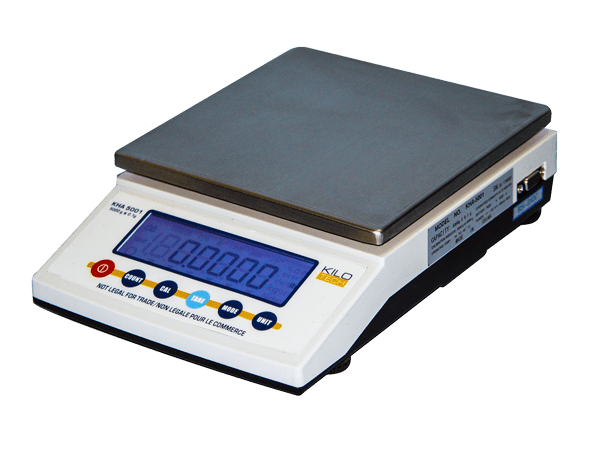

Anyload has been in business for over 20 years. Anyload is experienced in the design and production of high quality standard load cells, specialty load cells, weigh modules, indicators, scales for commercial and industrial applications, and wide varieties of weighing components.

At Coti Global Sensors, we are dedicated to providing top-of-the-line load cell solutions and comprehensive services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted authority in load cell manufacturing, renowned for our commitment to quality, reliability, and customer satisfaction.

More Torque Transducer Manufacturers

Torque transducers measure only one kind of torque. Very simply put, this kind of torque relates to rotational, or twisting, motion. Measuring torque is complicated because so many variables contribute to torque's generation. The measurement of torque is the measurement of the rotational force necessary to perform work; the measurement of torque depends on the size of the objects involved, the distance between them and many other variables.

Work, in the context of physics and mechanical engineering, has to do with the movement of a thing as a result of the movement of another thing, and torque is the measurement of the energy required to produce that movement. Torque transducers are very important in measuring the performance of engines. For example, in automobiles, the torque curve of an engine (which is the measure of torque while an engine operates) relates directly to the vehicle's acceleration capacity. Sport car designers and service personnel are concerned with measuring torque for this and other similar reasons.

Torque transducers must be inherently high performance devices. They are used to measure the performance of an engine, whether in a car or in a machine, but they defeat their own purpose if they interfere with that engine's performance. In order to measure the energy required to produce rotational movement, torque transducers must involve themselves in that movement.

An analogue to this situation is a golfer measuring wind speed and direction with an extended finger. To a very small extent, the extension of that finger interferes with the movement of the wind as it measures it. This interference is inconsequential in the measurement of wind speed, but it is very consequential in the measurement of torque; a poorly designed torque transducer can cause torque resistance, which can reduce an engine's performance.

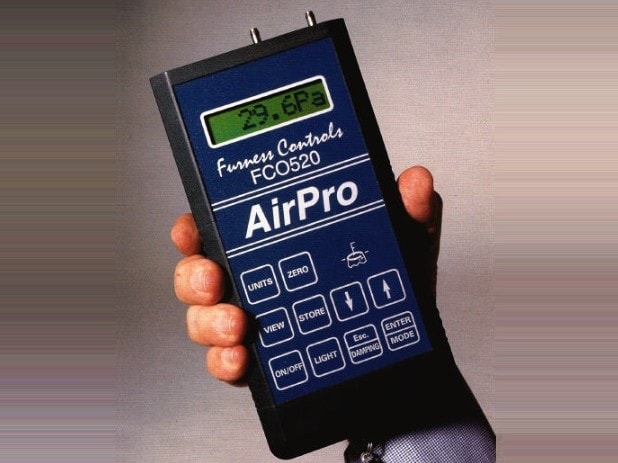

Engineers noticed this problem and responded with clever innovations that can measure changes in magnetic fields without coming into contact with the machinery being measured. Whatever their measurement method, all torque transducers must take their measurements and then transmit that information to a display that can be read by humans; in this way they are similar to pressure sensors and level transmitters. That display can be part of a computer in more advanced systems, or it can be a simple LCD screen with nothing more than numbers.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services