Cleveland Motion Controls, Inc.

Cleveland Motion Controls, Inc.Request A Quote

Cleveland, OH | 800-321-8072Cleveland Motion Controls, Inc. is a leading company specializing in the design, manufacturing, and distribution of load cell systems. With a rich history spanning several decades, we have established ourselves as a trusted name in the industry, delivering high-quality products and exceptional service to our clients worldwide. Our commitment to innovation, precision engineering, and customer satisfaction sets us apart from our competitors. At Cleveland Motion Controls, we understand the critical role that load cells play in a wide range of industries. Load cells are vital components used for measuring force and weight, ensuring accurate and reliable data in various applications. We have developed an extensive product line that caters to diverse industry needs, including manufacturing, aerospace, automotive, medical, research, and many others. Our load cells are manufactured with the highest standards of quality and precision. We utilize advanced technologies and employ a team of experienced engineers who are dedicated to creating innovative solutions. Every load cell we produce undergoes rigorous testing and calibration to guarantee its accuracy, durability, and long-lasting performance. Whether our clients require standard load cells or custom-designed solutions, we have the expertise and capabilities to deliver products that meet their unique specifications. Cleveland Motion Controls, Inc. is a leading load cell manufacturer with a strong emphasis on quality, innovation, and customer service. With our diverse range of high-precision load cell products, technical expertise, and commitment to meeting client needs, we are well-positioned to serve a wide range of industries. Whether it's a standard load cell or a custom solution, our clients can rely on us for superior products and exceptional support.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

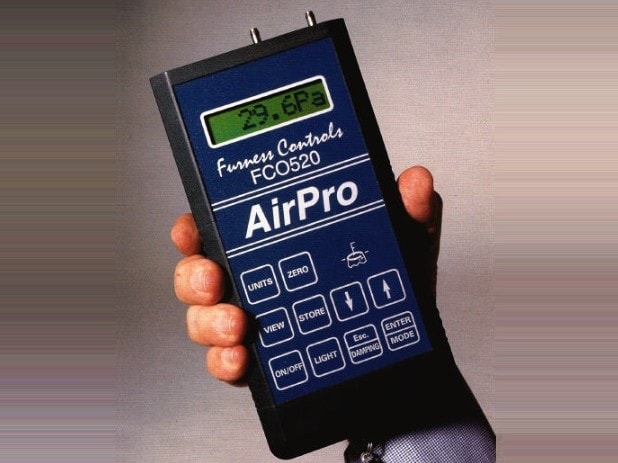

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

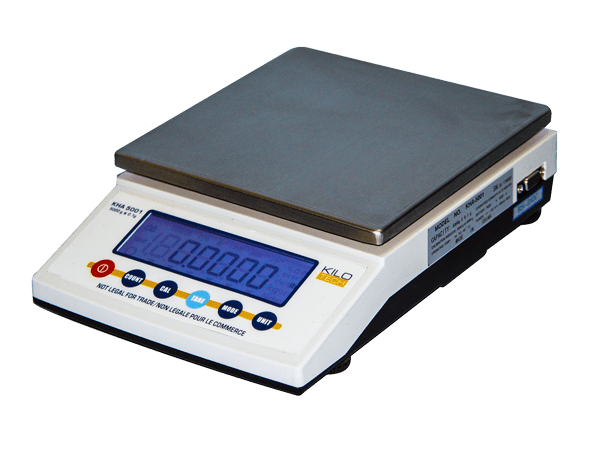

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services