Instron® Corporation

Instron® CorporationRequest A Quote

Norwood, MA | 800-877-6674Instron® Corporation is a leading global provider of testing equipment and solutions, specializing in the design, manufacturing, and servicing of load cells. With a rich heritage spanning over several decades, Instron® has established itself as an industry leader in the field of materials testing and measurement. The company's commitment to innovation, precision, and reliability has made it the preferred choice for customers worldwide. Instron® offers a comprehensive range of load cells that are designed to accurately measure force and load in various applications. The load cells are manufactured using advanced technologies and materials, ensuring exceptional performance, durability, and accuracy. Instron® load cells are utilized across numerous industries, including automotive, aerospace, construction, electronics, medical devices, and many others. One of the key strengths of Instron® lies in our extensive product portfolio. The company offers a wide range of load cell types to meet diverse customer requirements. These include tension and compression load cells, fatigue-rated load cells, miniature load cells, high-capacity load cells, multi-axis load cells, and custom load cells. Each load cell is engineered to deliver precise measurements under varying conditions, enabling customers to obtain reliable and repeatable test results. Instron® Corporation is a global leader in load cell manufacturing, offering a wide range of high-quality load cells for diverse applications. With its commitment to innovation, precision, and customer satisfaction, Instron® continues to be the preferred choice for companies seeking reliable and accurate force measurement solutions. Whether it is standard load cells or custom-designed solutions, Instron® Load Cell Manufacturers delivers unparalleled quality and service capabilities to meet the evolving needs of the materials testing industry.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

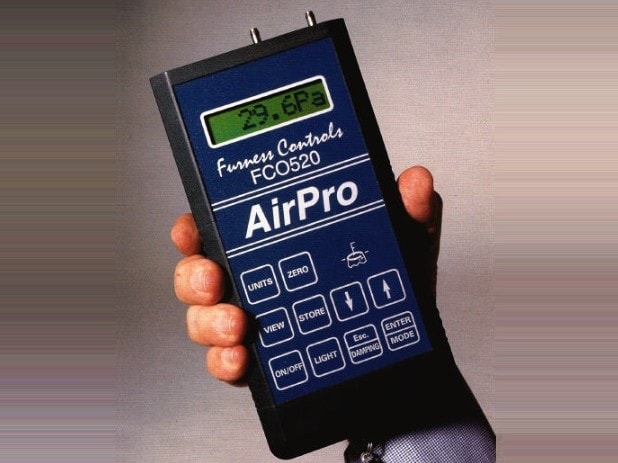

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

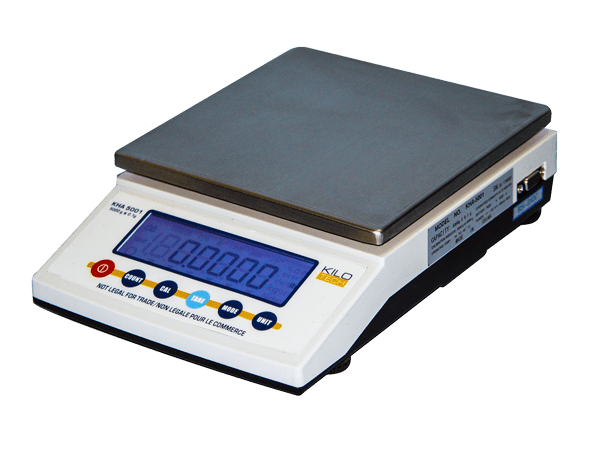

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services