Precision Calibration Systems

Precision Calibration SystemsRequest A Quote

Morristown, TNPrecision Calibration Systems is a leading provider of high-quality load cell products and calibration services. With a strong commitment to precision and accuracy, we specialize in the manufacturing of load cells and offer comprehensive calibration solutions to a wide range of industries. Our state-of-the-art facilities, experienced team of engineers, and cutting-edge technology enable us to deliver reliable and innovative load cell products and exceptional calibration services.: As load cell manufacturers, Precision Calibration Systems designs, develops, and produces a diverse range of load cells tailored to meet the specific needs of our customers. Our load cells are meticulously crafted using advanced materials and manufacturing techniques to ensure durability, accuracy, and long-term performance. We offer a wide selection of load cell types, including tension, compression, shear, bending, and universal load cells, catering to various load measurement applications. Our load cells are designed to provide accurate and precise measurements across a broad range of capacities, from small-scale applications to heavy-duty industrial environments. We understand the importance of reliability and repeatability in load cell performance, which is why we subject our products to rigorous quality control measures and testing procedures. By adhering to international standards and industry best practices, we guarantee that our load cells consistently meet or exceed customer expectations. At Precision Calibration Systems, we are dedicated to delivering superior load cell products and exceptional calibration services that exceed customer expectations. Through our commitment to quality, precision, and customer satisfaction, we have established ourselves as a trusted partner for load cell manufacturers and calibration services worldwide.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

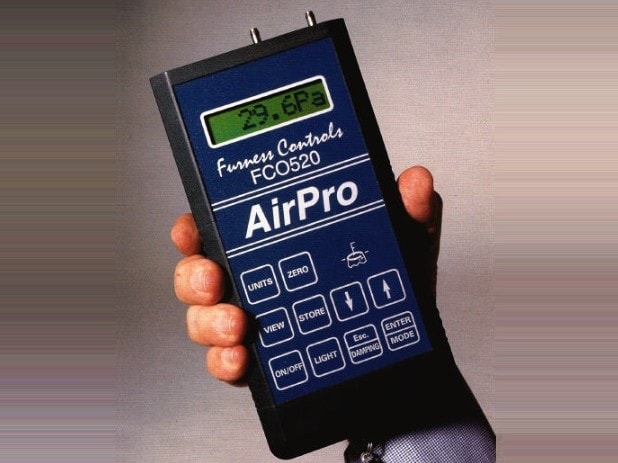

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services